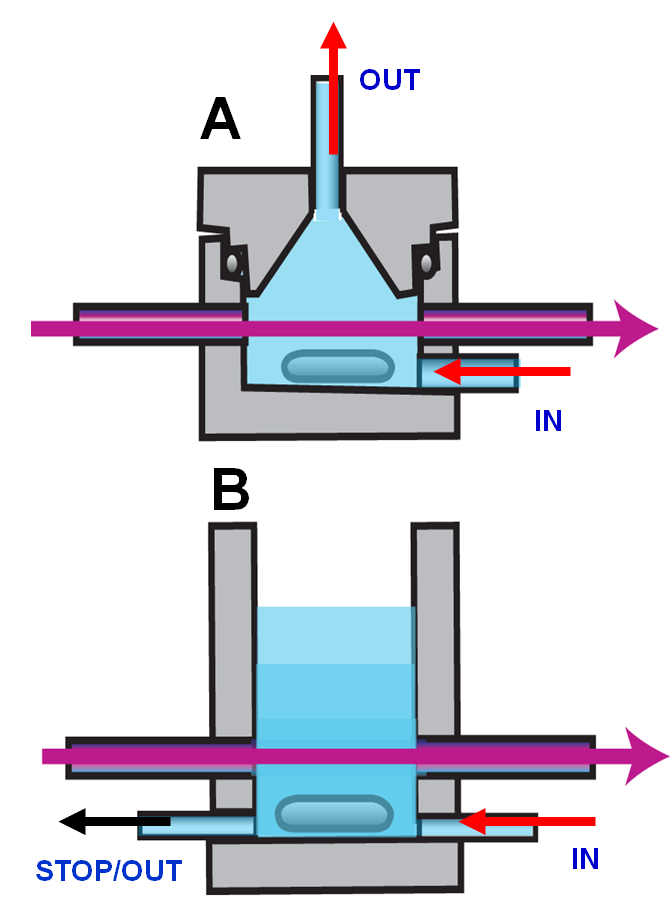

A well-mixed chamber that integrates reactor with detector can be operated in flow through mode or in batch mode.

The flow through chamber (A) has a fixed volume through which the carrier stream flows continuously during the measurement cycle. The monitoring of the exponentially falling concentration gradient, formed as the injected material passes through the reactor, has been exploited for automation of titrations, and continuous monitoring of biomass during fermentation (Baxter 1994).

The batch reactor (B) has a variable volume, since its outlet is closed, until the monitoring is completed. Sample and reagents entering the chamber are well mixed, yielding a homogeneous mixture, while the detector provides continuous readout. For reaction rate measurements, all reactants are injected into the reactor at the beginning of the measurement cycle (Yan Chen 2006, Polasek 2005). For titrations, sample is injected first, followed by a gradual, metered volume of titrant. Drawbacks of microreactor systems are mechanical complexity and lower sampling frequency.

Stirred MicroReactor Systems

2.3.16.